-

Your shopping cart is empty!

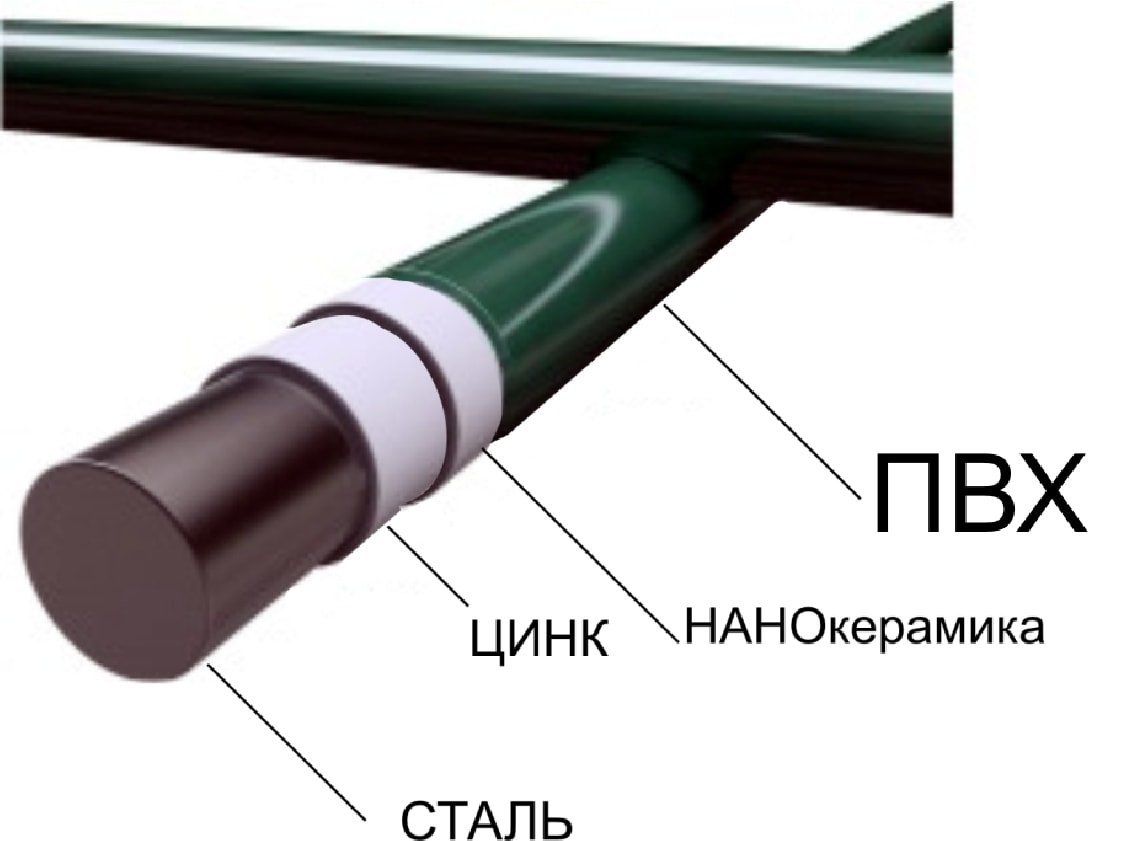

Advantages of PVC coating include

- optimal coating thickness of 500 µm:

- service life reaches 60 years

- excellent resistance to various drops

temperatures (from - 40° to +100° С )

- resistance of a color covering to fading;

- excellent tolerance to various types of climatic conditions;

- meshes with PVC are not affected by alkalis and a large amount of acids, as well as various solvents and oils of mineral origin.

- Moreover, the presented coating incorporates special impurities that give the product increased frost resistance, a layer thickness of 500 microns or more provides better protection against corrosion;

- the coating is sufficiently elastic: it does not crack and does not peel off during transportation, installation:

- PVC structure makes the fence more weather resistant

To cover the grid with a PVC solution, a panel of galvanized wire at a temperature of 320 ° C is immersed in a container with 99% chloropolyethylene. The connections between the galvanized steel wire and the PVC coating have an additional layer of nano-ceramics, which ensures a reliable connection of zinc + polymer. As a result, the mass adheres tightly to the wire, forming an even layer.

PVC coating is visible to the naked eye!

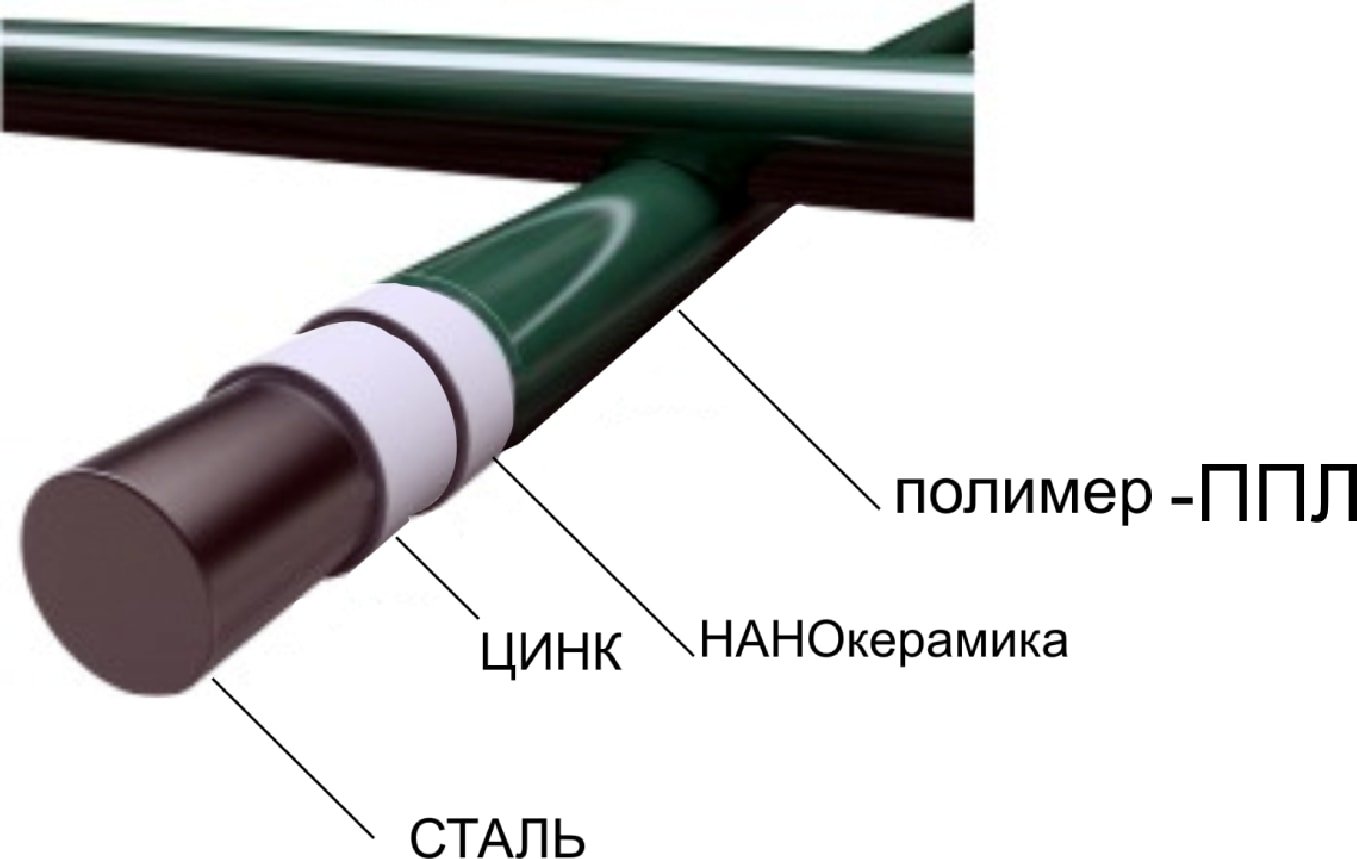

The benefits of PPL coatings include

- does not contain harmful organic compounds;

- The service life of the coating in an industrial atmosphere of medium aggressiveness for up to 30 years.

- high anti-corrosion resistance to moisture, alkali and acid solutions, organic solvents.

- coating thickness 60...80 microns;

- the possibility of painting in any color, the range is not less than 5000 colors of the RAL catalog.

- Does not respond to sudden changes in temperature and environmental factors.

- Products painted with powder paints do not require additional care.

To spray the PPL coating, the paint is applied to the grid under the influence of an electrostatic field. The connections between the galvanized steel wire and powder coating have an additional layer of nano-ceramics, which ensures a reliable connection of zinc + polymer. After application, the product is baked in an oven at a temperature of 180-200 C; However, the reduction in elasticity with this method of coating leads to a greater likelihood of damage during installation or transportation. The indisputable advantage of PPL coating is the lower cost of the process.

PPL advanced polymer coating!